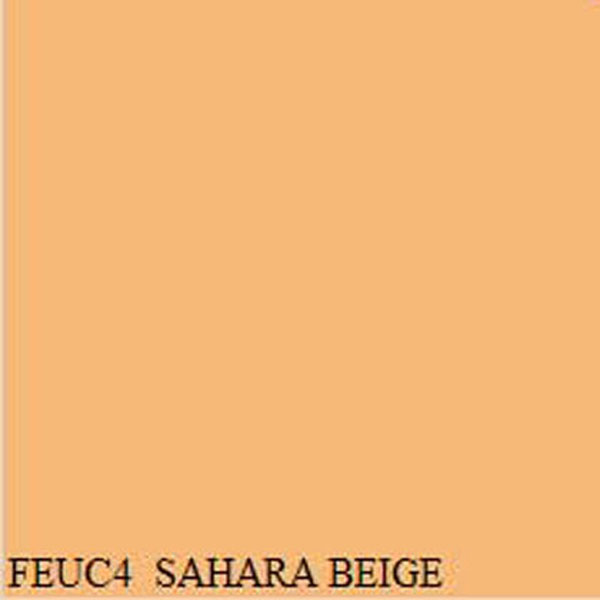

FORD FEUC4 SAHARA BEIGE

£0.00

Mirrorcryl 2k acrylic kits – A tough two pack high performance acrylic enamel for automotive, commercial vehicle and equipment.

Mirrorlaq kits– Quality Nitrocellulose for automotive, bike commercial vehicle part repairs or repaints.

Mirrorfast kits – Air dry thermoplastic acrylic.

Cv poluethane enamel Kits – Commercial vehicle paint Highgloss from the gun spray paint.

Cv coachpaint – Traditional Exterior brushing Coachpaint product slow drying high gloss for Bus, coach, Machine and equipment .

Lazergloss Brushable – Quickdrying product for application to wide range of substrates ,wood , metal.

Description

Solid colour products

Mirrorcryl 2k Mixing kits

Automotive transport ,truck and commercial and Locomotive colour range.

A tough two pack high performance acrylic enamel for automotive, commercial vehicle and equipment. New work and refinishing for universal application.

Exceptional colour matching and uv resistance is a key feature of this durable hi gloss product .

The high standard to be met by commercial and original equipment finishes are reflected in the chemical resistance and abrasion resistance of Mirrorcryl. Slow thinner may be needed to refinish larger vehicles to aid longer wet edge time.

Mixing Instructions

Mirrorcryl mixed colour 100 parts

Mirrorcryl MS Hardener 50 parts

Every thinner fast 50 parts

Every thinner slow 50 parts

Application Substrates

Mirrorcryl ready mixed colours can be applied over sanded original finishes except thermoplastic acrylic. – Sanded fibreglass surfaces. – Washfiller etch – Hi-Fil 2k Primer – Anti-corrosive primer – Zp Primer Shades – Tempo Filler Shades

Surface preparation

Degreaser with Quickwipe degreaser then Dry sand with p320-p400 grade paper. Wet sand with P800 or P1000 grade paper. Application Mixing Instructions Mixing ratio is 100 parts base: 50 parts activator by volume, 10 -20% thinner of total volume. The mixed material is then ready for application normal pot life up to 4 hours AT 20°c apply 2 full coats 20 mins between each coat.”

Mirrorlaq Ready mixed

Quick drying Quality Nitrocellulose for automotive, bike commercial vehicle part repairs or repaints , Industrial general machine and implements work and exterior woodwork, extremely fast flash-off and polish to a full gloss.

Mixing Instructions

Mixing ratio is 100 parts Mirrorlaq 100-100 parts Mirrorfast thinner.

With some colours, a greater amount of thinner will enhance the sprayablity flow and polishablity.

Metallic colours mixing ratio is 100 Mirrorlaq 150 parts Mirrorlaq thinner.

Application process

Spray single coats until full opacity is achieved (with most colours 3-4 single coats is sufficient). Flash off times will vary depending on temperature, the type of thinners used and conditions of application, please allow each coat to become touch dry before applying the following coat.

See colour listing below:

Mirrorlaq is normally mixing in all solid colours (i.e. red blue green), we can mix Metallic and Pearlcoat colours with restrictions that it would be a repaint match only.

Mirrorfast ready mixed

Quick air drying TPA acrylic enamel for automotive part repairs or repaints; Industrial work and exterior woodwork, extremely fast flash-off and polish to a full gloss. Based on non yellowing acrylic enamel this product is durable easy to use and easy to blend.

Appearance

Full Gloss , Satin and matt are available ,

Additives

107.005 – Mirrorfast fast thinner – for normal speed and performance and high gloss.

Coverage

Coverage of 8-9m sq/mtr per ltr per coat

Application Substrates

Mirrorfast ready mixed colours can be applied over sanded and degreased original finishes.

-Tempo-filler shades

-Washfiller etch.

Surface preparation

Degrease with Quick wipe degreaser.

Dry sand with p320-p400 grade paper.

Wet sand with p800-p1000 grade paper.

Degrease with Quick wipe degreaser.

Mixing Instructions

Mixing ratio is 100 parts Mirrorfast 100-150 parts Mirrorfast thinner.

With some colours, a greater amount of thinner will enhance the sprayablity, flow and polishablity.

Metallic colours mixing ratio is 100 Mirrorfast 150 parts Mirrorfast thinner.

Spraying viscosity

12-15s Din cup 4 at 20°c (15-19s BSB4 cup)

Spray gun fluid tip and working pressure

tip pressure

Gravity feed Spray gun 1.5mm 2-4 bar

(30-60 psi)

Suction feed Spray gun 1.8mm 2-4 bar

(30-60 psi)

Application process

Spray single coats until full opacity is achieved (with most colours 3-4 single coats is sufficient). Flash off times will vary depending on temperature, the type of thinners used and conditions of application, please allow each coat to become touch dry before applying the following coat.

Satin and Matt colours must have correct film thickness.

Blending and fading out techniques:

Fade-outs are extremely easy with Mirrorfast, Reduce pressure to (5-7psi), dissolve by fading pure Mirrorfast slow thinner immediately after last coat.

Drying

Dust free 5 mins

Tack free 15 mins

Touch dry 30 mins

Recoat ability.

Recoatable after correct flash-off times

Polishing

Areas may have a light flat with P1200 Wet or Dry and polished when dry with reflection finishing surfaces.

CV Polyurethane Ready mixed

CV Polyurethane mixed colour to colour listing below Autocote thinner

Description

C.V Polyurethane is an advanced formula One Pack Synthetic Enamel with fast drying properties, suitable for Car and commercial vehicles Trucks and vans, Machinery, Implement and metal equipment Full Gloss

Coverage

Coverage of 8-10m sq/mtr per ltr per coat

Application Substrates

C.V Polyurethane ready mixed colours can be applied over sanded original finishes, except thermoplastic acrylic which requires the application of a barrier coat.

– Washfiller Etch -on steel or aluminium alloys

– ZP Primer (Shades) (zinc phosphate)

– Mirrorcryl Hi- Fil primer (2k)

– Anti-corrosive primer.

– White groundcoat is needed on fluorescent colours

Surface preparation

Dry sand with p320-p400 freecut paper

Wet sand with p800-p1000 wet or dry paper.

Recoat wet on wet (non sand) primers when flash-off times have been observed.

Spraying Viscosity

C.V Polyurethane ready mixed colours can be thinned 5-1 to a spraying viscosity of 20-28 secs Din4 at 20°c (25-35 secs BSB4 Cup).

Hot Spray Application

Hot application is possible when the product is heated to a temperature of 60-70°c, and one full coat is applied, no thinning is required.

Brush Application

Apply at unthinned viscosity using a large brush. 2 coats is normally applied

To slow cv polyurethane an addition of 10% slow thinners is recommended.

Application

Spray one single medium coat allowing 20 minutes flash off (until touch dry).

Spray one further full wet coat to full gloss, or double header coat.

Drying

20°c metal temperature

Dust free 40 mins

Tack free 4 hr

Tape time 6 hrs

Hard dry 16 hrs

CV Coachpaint Ready mixed

CV Coachpaint mixed colour to colour listing plus WS Thinner

Description

C.V Coachpaint is an advanced formula One Pack Alkyd Synthetic Enamel with fast drying properties, suitable for commercial vehicles Trucks and vans, Machine and implements, wood and steelwork, Cladding, Joinery products, Exterior building structures, fascias, garden structures, Rail and heavy goods vehicles,

This is a traditional Coachpaint for brushing or spraying product slow drying High gloss.

Spraying Viscosity

C.V Coachpaint ready mixed colours can be thinned 5-1 to a spraying viscosity of 20-28 secs Din4 at 20°c (25-35 secs BSB4 Cup).

Application Substrates

C.V Coachpaint ready mixed colours can be applied over sanded original finishes, except thermoplastic acrylic which requires the application of a barrier coat.

– Washfiller Etch -on steel or aluminium alloys

– ZP Primer (Shades) (zinc phosphate)

– Mirrorcryl Hi- Fil primer (2k)

– Anti-corrosive primer.

– Mirror clad MIO Coating

– W/B MIO Armour plate primer.

– Plaz plastic primer on rigid plastic components

– White ground coat is needed on fluorescent colours

Surface preparation

Dry sand with p320-p400 freecut paper

Wet sand with p800-p1000 wet or dry paper.

Hot Spray Application

Hot application is possible when the product is heated to a temperature of 60-70°c, and one full coat is applied, no thinning is required.

Brush Application

Apply at unthinned viscosity using a large brush. 2 coats is normally applied

An addition of 10% WS Thinners is recommended.

It is possible to only apply one coat if a correct colour undercoat is used first

Lazergloss Brushable

Description

An exterior durable brushable finish in a range of beautiful Gloss Satin of Matt finishers.

Hard and tough and fast drying makes it a Ideal Industrial/ Decorative coating for Woodwork, metalwork repairs and Industrial Applications, Use in model painting. Base on a non Yellowing and Blend of solvents

Products

Lazer gloss is available in a wide variety of colours

Also the product is available in full range of solid colours, British standard colours and RAL Colours, Pearlcoat translucent and specialist colours to order.

Computer colour match are now achievable using your colour standard sample provided.

Substrates to which this Product can be Applied

Woodwork

ZP Primer Shades

Anti-corrosive primer

Primed metalwork and most painted and cured finishes

Surface Preparation

Surfaces should be free of all loose dust and smooth, normal with p400 freecut paper.

Mixing Ratio

The product is supplied Ready for use but can be thinned if longer Brushability is required with up to 10% WS Thinner

This product is traditionally a brush applied material but can be spray applied by using alternatively Mirrorfast Thinner as the solvent for spray.

This is mixed 1-1 please note when sprayed approx. 4 coats is equal to one coat brushed.

Application process

By Brush

Apply 3 coats with a drying time between coats of 3 hour at 20°c centigrade

When each coat is dry it can be sanded with p400 or Fibral hand pads (ultra Fine).

If a matched coloured undercoat (ZP Primer Shades) is used it is possible to used less coats to achieve coverage.

Finishing process

After the product has dried, any small contamination in the coating may be sanded with P2000 microfine abrasive and then polished to a finish with Mirror Reflection finishing Surfacer.

Additional information

| Dimensions | 200 × 110 × 120 mm |

|---|---|

| Colour |